-

Carbide Milling Inserts

-

Tungsten Carbide Inserts

-

Milling Cutter Carbide Inserts

-

Indexable Milling Inserts

-

Cemented Carbide Inserts

-

Indexable Carbide Inserts

-

High Feed Milling Inserts

-

Chip Breaker Inserts

-

Carbide Inserts For Aluminum

-

Carbide Turning Inserts

-

CNC Carbide Inserts

-

Woodworking Carbide Inserts

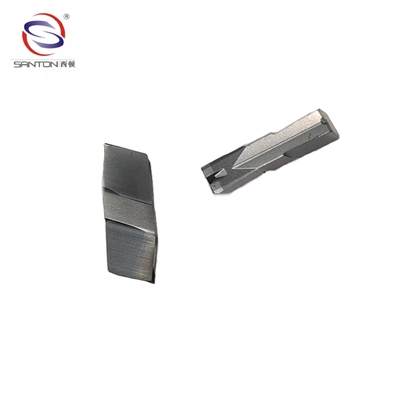

GIP4.00-0.40-AN4 Black Coated Double Sided CNC Carbide Inserts For Cutting Edge

| Place of Origin | Sichuan, China |

|---|---|

| Brand Name | Grinding double head slotting cnc cutting tools |

| Certification | ISO9001 2008 |

| Model Number | GIP4.00-0.40-AN4 |

| Minimum Order Quantity | 100pcs |

| Price | 16-20 CNY/piece |

| Packaging Details | plastic box,A box of ten tablets |

| Delivery Time | 20-25 working days |

| Payment Terms | T/T |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Insert Width | 6mm | Insert Height | 3mm |

|---|---|---|---|

| Material | Carbide | Cutting Edge Angle | 90° |

| Cutting Edge Length | 2mm | Coating | TiN |

| High Light | Cutting Edge CNC Carbide Inserts,Black Coated CNC Carbide Inserts,TiN Coated Carbide Machining Inserts |

||

GIP4.00-0.40-AN4 Black Coated Double-Sided CNC Carbide Inserts Used For Cutting Edge

Product Description:

CNC Carbide Inserts feature a ground plate with a coating of TiN, making them highly durable and long-lasting. Their cutting direction is right-hand and they have 4 cutting edges, with a double-sided cutting edge type. The weight of each insert is 2g. CNC Carbide Inserts are designed to provide superior performance and extended tool life. With advanced coating technology and superior materials, they are perfect for creating high-precision, high-quality cuts.

Features:

- Product Name: CNC Carbide Inserts

- Cutting Direction: Right Hand

- Coating: TiN

- Insert Thickness: 3mm

- Cutting Edge Angle: 90°

- Cutting Edge Type: Double-Sided

- Inserts for turning operations

- High-performance coated carbide inserts

Technical Parameters:

Grade Information

| Grade | Performance typical value | Characteristics & Applications | ISO Code | Equivalent Grades | ||

| Density (g/cm3) | TRS (N/mm2) | Hardness (HRA) | ||||

| ST1040 | 14.3-14.55 | 3300 | 91.5-92.5 | Ultra-fine alloy, high strength, good impact resistance, good shock resistance, good wear resistance, suitable for gray cast iron, ductile cast iron, non-ferrous metal finishing and strong milling, non-metallic material roughing (suitable for low and medium speed, large feed amount, deep cutting depth of roughing) | K20-K40 | |

| Grade | Performance typical value | Characteristics & Applications | ISO Code | Equivalent Grades | ||

| Density (g/cm3) | TRS (N/mm2) | Hardness (HRA) | ||||

| SK30UF | 14.3-14.55 | 2800 | 91.5-92.5 | Extra fine substrate,high strength,good resistance to impact,vibration,and wear,roughing and heavy milling for gray cast iron,nodular cast iron, non-ferrous metal, roughing for non-metallic materials. | K30 | ZK30UF /YG10X |

Applications:

Grinding double head slotting CNC cutting tools are essential for many industrial processes, such as cutting, drilling, shaping, and finishing metal and other materials. CNC Carbide Inserts, such as the Grinding double head slotting CNC cutting tool Model Number N123G2-0300-0002-GF, are made from the highest quality tungsten carbide material, giving them an edge over other cutting tools. With its four cutting edges, the CNC Carbide Inserts are designed to handle a wide range of materials, including steel, aluminum, brass, and other materials, without compromising the quality of the cut. The insert is designed to deliver precision cuts with a sharp radius of 0.2mm and a weight of 2g. It also features a thickness of 3mm and is coated with a protective coating to ensure maximum durability. The Grinding double head slotting CNC cutting tool is the perfect solution for any industrial process that requires precision and accuracy, and its coated CNC Carbide Inserts are reliable and durable enough to withstand the toughest of tasks.

Support and Services:

We provide technical support for our CNC Carbide Inserts to ensure that our customers are able to use our products to their fullest potential. Our team of experienced professionals is available to answer any of your questions, provide advice for any challenges you may face, and provide helpful tips to make sure your CNC Carbide Inserts are used correctly and achieve the desired results.

We also offer a variety of services to help maintain the quality of your CNC Carbide Inserts. Our team can help inspect and test the quality of your inserts to ensure they are up to standard and working properly. We also offer repair and replacement services for any of our CNC Carbide Inserts that may have been damaged or are not working correctly.

We strive to provide the best customer service and technical support for our CNC Carbide Inserts. We understand that our customers need reliable and efficient products, and we are committed to providing the best service and support to make sure they are satisfied with our products.

Packing and Shipping:

Packaging and Shipping of CNC Carbide Inserts

At XYZ Inc., we provide custom packaging and shipping of CNC carbide inserts to ensure that your product arrives safely and in perfect condition.

Our packing materials are designed to protect the product from damage during transit. We use bubble wrap, foam, and other protective materials to ensure that your product is safe and secure during shipping.

Our shipping personnel are highly trained and experienced, and they understand the importance of delivering your product in a timely manner. We use reliable carriers such as UPS and FedEx to ensure that your product reaches its destination safely and on time.

We understand that your product is important to you, and we take the utmost care in packaging and shipping it to you. Thank you for choosing XYZ Inc. for your CNC carbide insert needs!

FAQ:

- Q: What are CNC Carbide Inserts?

- A: CNC Carbide Inserts are specially designed cutting tools for CNC machining. They are made of tungsten carbide, which is a kind of hard metal material, and have an extremely sharp cutting edge.

- Q: What is the Brand Name of Grinding double head slotting cnc cutting tools?

- A: The Brand Name of Grinding double head slotting cnc cutting tools is Grinding double head slotting cnc cutting tools.

- Q: What is the model number of Grinding double head slotting cnc cutting tools?

- A: The model number of Grinding double head slotting cnc cutting tools is N123G2-0300-0002-GF.

- Q: Where are CNC Carbide Inserts made?

- A: CNC Carbide Inserts are made in Sichuan, China.

- Q: What are the advantages of CNC Carbide Inserts?

- A: CNC Carbide Inserts have a longer service life and higher cutting efficiency than other cutting tools, and they are also more cost-effective.